Edge prep benefits:

Ability to run higher feed rate with reduced torque

Longer tool life

Eliminate chatter

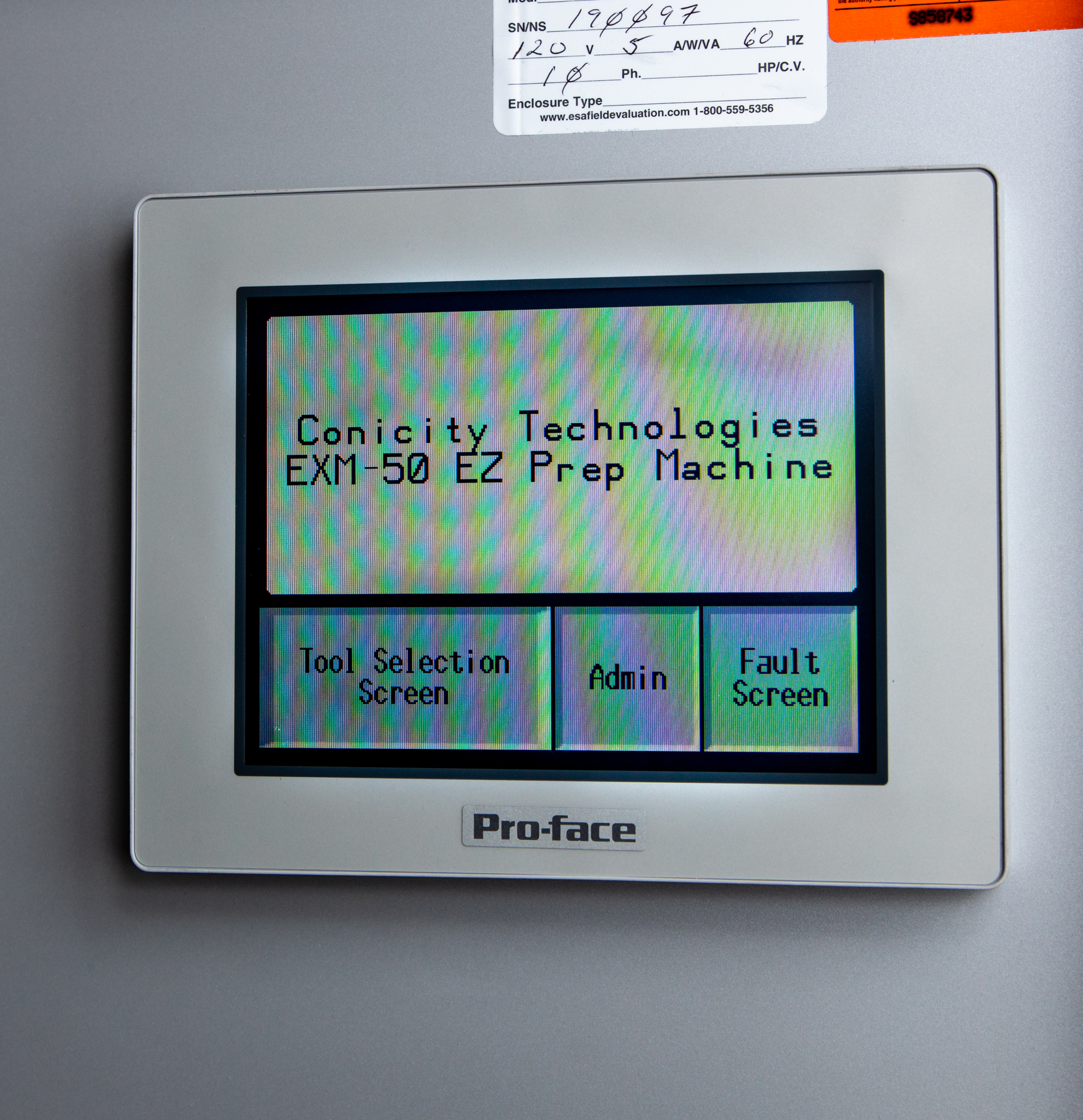

machine capabilities:

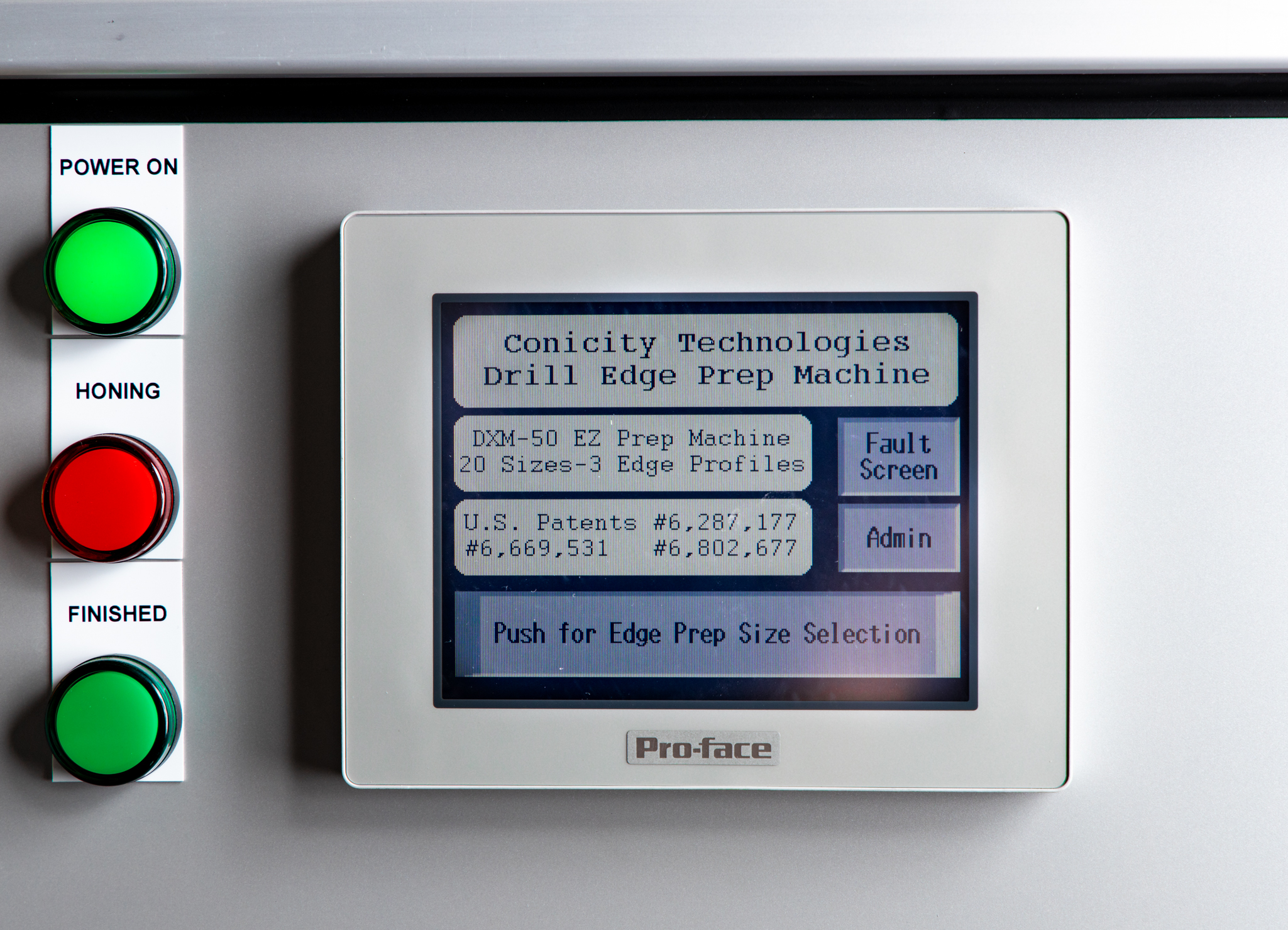

Size selection includes 4 edge prep sizes.

The current waterfall edge prep technology for end mills covers 4 distinct edge prep sizes for both Right and Left Hand cutting tools.

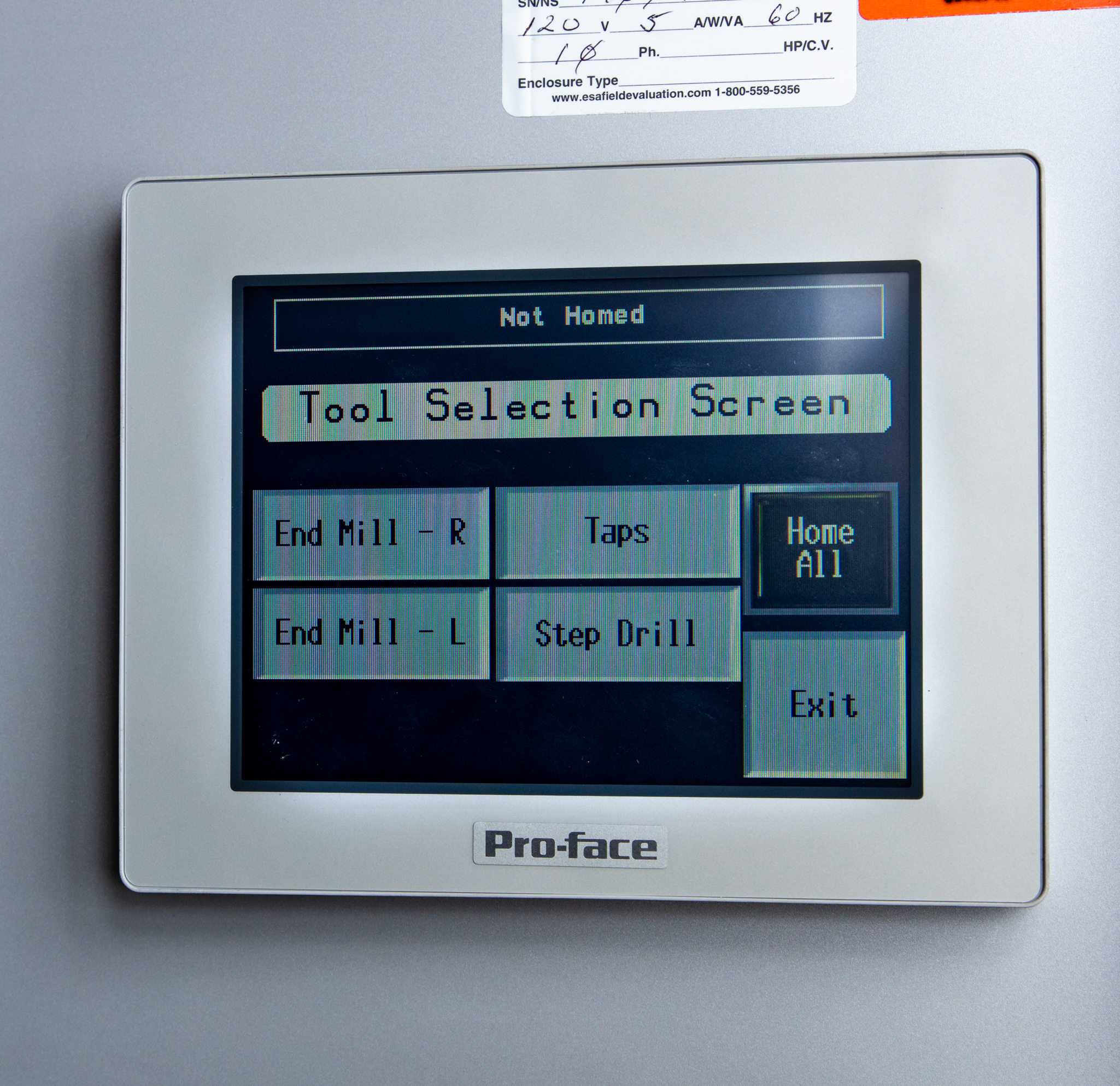

End Mills

Any manufacturer’s helix/external form including variable pitch/variable spaced end mills.

Right hand/Left Hand Rotation

Size range from 1 MM to 30 MM Diameter, ½” to 10-1/2” flute length.

Ball Nose End Mills

Left and Right Hand

Steps on Step Drills/Step Reamers

Up to 5 steps

Thread Mills

Any manufacturer’s configuration

Up to 25 MM Diameter, multiple flutes

Taps

Up to 25 MM Diameter

Utility requirements:

Standard 110VAC Single Phase Current

15 AMP service line

Normal Wall Outlet (Non-GFI)

Work Light 110 VAC 35 Watt

European current (50hz acceptable)

Machine requires only the electrical plug end changed to adapt to the local electrical supply standard.

Unit is sealed, no dust collection required.

CE Certified